Hand lay up process for fiberglass pdf

Fiberglass For Hand Lay-up Home >Products>Process >Fiberglass For Hand Lay-up. Chopped Strand Mat 100GSM. Application: Automotive Headliner Compatibility: PU. Learn More. Emulsion Chopped Strand Mat. Emulsion Fiberglass Chopped Strand Mat for Profile GRP Sheeting, trimed edge or untri… Learn More. E Glass Woven Roving. E Glass Woven Rovings are bidirectional fabric made …

Hand lay-up is the most common and least expensive open-molding method because it requires the least amount of equipment. Fiber reinforcements are placed by hand in a mold and resin is applied with a brush or roller. This process is used to make both large and small items, including boats, storage tanks, tubs and showers.

corrugated fiberglass roofing sheets, now days, manufacturing by Hand Lay-up process, this process done by manually with the help of equipments, it consists of open mold, brush, squeeze roller.

Hand lay-up is used for mold production, complex shapes, and low volume production. The fiberglass is wet out with resin and placed in the mold. Rollers and brushes are used to remove all bubbles and to make sure thickness is the same throughout.

Custom manufacturer of hand lay-up fiberglass. Capabilities include design, engineering, compression molding, tooling fabrication, process and prototype development, assembly and project management. Other services include wind blade and composite repair, inspection and cleaning. JIT and Kan Ban delivery services are available. Made in the USA.

Clarifier, FRP Clarifier, GRP Clarifier manufacturer / supplier in China, offering FRP or GRP Clarifier Made by Hand Lay-up Process, Horizontal Type FRP Tank Making Machine, FRP Tank Making Machine – Vertical Type for Large Fiberglass Tanks and so on.

So, we have a fiberglass structure that we have been working on using these same techniques, and we are adding a reinforcement fiberglass hand-layup to strengthen this fiberglass corner. This instructable / tutorial is intended to be not necessairly specific to airplane building.

Fiberglass Surface Mat, Fiberglass, Glass Fiber Tissue manufacturer / supplier in China, offering Soft Type 30GSM Fiberglass Tissue for Hand Lay-up Process, High Strength 2400tex Fiberglass Panel Roving Fibreglass, Assembled Fiber Glass Roving for Spray up and so on.

FFI utilizes hand lay-up and vacuum infusion molding processes to produce a wide range of FRP products. With in-house tooling fabrication, FFI can custom mold components as needed without the high tooling costs.

One of the challenges of hand lay-up process is to obtain the right resin/glass ratio in each application. In order to control the ratio, below methods can be followed;

In hand lay-up processing, fiberglass (typically E-glass) continuous strand mat and/or other fabrics such as woven roving are manually placed in the mold. Each ply is sprayed with Catalyzed resin (1000 to 1500 cps) and the resin is worked into the fiber with brushes and rollers to …

Fiberglass reinforced plastic, commonly known as fiberglass, was developed commercially after World War II. Since that time, the use of fiberglass has grown rapidly. thermo set pla st ic r esi n t ha t is reinforced with glass fibers. In this manual, the more general te rms Fiber Reinforced Plastic/ Composites or FRP/Composites will be used to describe these extremely useful material systems

EBB 427 Application and Technology of Engineering Polymers (Second Half) Hand lay-up Dr. Hazizan Md Akil School of Materials and

resin vacuum introduction process and hand lay-up process

HAND LAY-UP OF FIBERGLASS PARTS ON A MOLD 1 FGCI

fiberglass resin impregnating technique The following video demonstrates the basic lay-up technique to fabricate a fiberglass laminate. The fabric to resin ratio was carefully calculated to yield a maximum of 35% resin content and process demonstrate how to produce low porosity or entrapped air bubbles (large voids and microscopic porosity) within the laminate.

7/10/2006 · I can’t stay on Hand lay-up. If I do that, I will lose my client. My plant is located in a small city and it’s very hard to find qualified workers.

HAND LAYUP: Hand layup is an open contact molding in one-sided molds are the lowest-cost and most common processes for making fiberglass composite products and is the most common method of producing composites parts in the U.S. aircraft industry.

Open molding is a low cost and effective method to manufacture composites. Open mold processes include, spray-up (chopping) and hand lay-up. This well established molding method is used to produce, boats, RV components, truck cabs and fenders, spas, tubs, showers, and other fiberglass …

Hand lay up or spray up is sometimes used as a preliminary step to full production or for fabricating prototypes. liquid wax or PTFE/silicone spray). . The gel coat is followed by a layer of resin and then of reinforcing agent.Following application of the liquid release agent (PVA.

Fig. 3 – Spray-up process (Lubin, p. 351) The wet hand layup process is uneconomical if many parts are to be manufactured, and an extension of the layup idea leads to the “spray-up…

Hand Lay-Up Process This guide provides a basic introduction on how to use FireShield for the fabrication of composites using the Hand Lay-Up process using polyester and vinyl ester resin systems reinforced with glass fibre.

Hand Lay~Up and Spray~Up Fabrication Submit a Listing to the Exchange The International Fiberglass Exchange (IFE) is a member based world wide information exchange designed for companies and individuals who BUY / SELL / TRADE goods and commodities.

Wet Hand Lay-up (HL), which is a low-investment process, compete favorably s with Vacuum Infusion (VI) or resin transfer molding processes, which require high tooling expenses. However, technology, VI

Open contact molding in one-sided molds is a low-cost, common process for making fiberglass composite products. Typically used for boat hulls and decks, RV components, truck cabs and fenders, spas, bathtubs, shower stalls and other relatively large, noncomplex shapes, open molding involves either hand layup or a semi-automated alternative, sprayup.

Each is constructed from hand-laid layers of fiberglass cloth. Fiberglass parts are produced in molds through a manual process known as a lay-up. To prepare the mold, it is coated with a release agent and then a gel coat is applied. This layer is then followed by a coating of resin or epoxy. Before setting, fiberglass cloth, which is impregnated with the same resin or epoxy, is laid on the

“Hand Lay-Up” is the most widely used molding process because of the cost effective tooling and is able fit almost every application. The tool side will have …

Paddle Rollers For FRP Hand Lay Up Process is widely used in frp industry. Our Paddle Rollers For FRP Hand Lay Up Process are popular in many countries such as Austrialia,Canada,UAE,Malaysia,Thailand, etc.

The easiest way to lay up a fiberglass hull is by hand in an open mold. The resin itself can be applied in different ways. The crudest method is to simply slap it on with brushes from buckets of catalyzed resin. Now, however, it is more common to see workers wetting out fabric with airless spray guns or special resin-fed rollers. With spray guns the resin and catalyst are mixed as they are

Epoxy Resin, Hardner, China Epoxy Resin manufacturer / supplier in China, offering Good Performance Epoxy Resin for Hand Lay-up Process, High Strength 2400tex Fiberglass Panel Roving Fibreglass, Assembled Fiber Glass Roving for Spray up and so on.

Fiberglass Mat Mat is the most versatile and widely used form of fiberglass for the hand lay up procedure. Mat is made up of short, individual fiberglass that can be hand laid in place. We stock Mat in tow weights. ¾ oz. and 1 ½oz. per square foot. Mat is used in applications where strength and durability are required, such as, on work decks for commercial and sport fishing boats, cabin tops

Wet Layup Overview. Exposure to the toxic resins, corrosive hardeners and catalysts, and fibrous reinforcement materials used in the wet layup process can be hazardous to your health.

Wet Layup TotalBoat

Hand lay-up is a simple method for composite production. The process consists The process consists of building up or placing layers of composite fiber in a sequenced layup using a matrix of

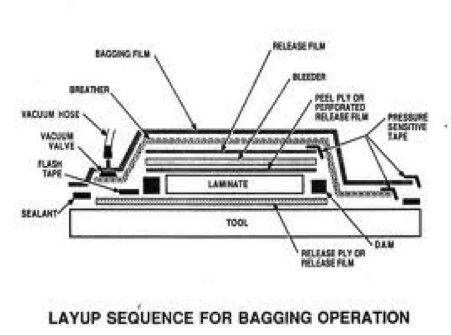

Fiberglass Hand Lay Up For Canoe and Kayak Building- Cedar Strip Kayak Fiberglassing – YouTube. Video will open in a new window . Basic Hand Lay-up Fiberglassing. Video will open in a new window. VACUUM BAGGING PROCESS For performance critical application used in aerospace vehicles, composite framing for automotive vehicles and marine vessels, a process called ‘Vacuum Bagging’ …

About 96% of these are fiberglass cloth, 3% are other fiberglass products, and 1% are fiberglass mat. A wide variety of fiberglass woven roving for hand lay up process options are available to you, such as fiberglass mesh cloth, blind, and wall/roof covering cloth.

Fiberglass delivery box. Fiberglass deliver box are made by skilled hand lay-up process.Our Fiberglass delivery box/FRP delivery box used for fast food,pizza delivery and motorcycle carrying box,Courier delivery box

Hand lay-up is the simplest and oldest open molding method of the composite fabrication processes. It is a low volume, labor intensive method suited especially for large components, such as boat hulls. Glass or other reinforcing mat or woven fabric or roving is positioned manually in the open mold, and resin is poured, brushed, or sprayed over and into the glass plies. Entrapped air is removed – ladder yarn necklace instructions Hand lay-up lamination The contact lamination process starts when a layer of gelcoat is applied. The first layer gives required colour, glossy surface and protects the element againts UV radiation and adverse atmospheric conditions or any other agent that may be harmful (for example sea water).

The hand layup of pre-impregnated woven materials is still a large part of the composite manufacturing industry, requiring the skills and experience of a human workforce to form flat plies into complex shapes.

hand lay up laminate regardless of the type of laminate being joined. If the If the vessel is specified as a Type I laminate (all chop strand mat), then a Type I

27/07/2016 · The wet lay-up facilities allow us to fabricate a wide variety of small scale composite systems. The work surface is a slab of nonstick polyethylene with full extraction. Plus there are

HAND LAY-UP OF FIBERGLASS PARTS ON A MOLD 1. PREPARING THE MOLD Remove dust and dirt from mold. If mold is of plaster, wood, or new fiberglass, apply

Fiberglass Tissue, Fiberglass Wet Tissue, Fiberglass Surface Mat manufacturer / supplier in China, offering 30GSM Fiberglass Surface Tissue for Hand Lay-up Process, 15mm Thickness PP Honeycomb for Bus Floor, Fiberglass Geogrid with CE Certificate and so on.

The difference between unsaturated polyester resin vacuum introduction process and hand lay-up process The process of introducing vacuum into the resin is to spread “dry” reinforcing material (glass fiber, carbon fiber, sandwich material, etc., different from the vacuum bag process…

Fiberglass Woven Roving For Hand Lay Up Process

Hand Lay~Up and Spray~Up Fabrication fiberglass.com

Composite Fabrication Hand Lay Up / Wet Lay Up

Hand lay-up of glass fibre demonstration YouTube

Changzhou Utek Composite Co. Ltd.

jjmechanic.com Composite Manufacturing Process Hand lay

30GSM Fiberglass Surface Tissue for Hand Lay-up Process

https://en.wikipedia.org/wiki/Fiberglass_molding

Hand Layup Fiberdome Incorporated

– Hand Lay Up Resin / Fiberglass Ratio BOYTEK A.Ş.

Hand Lay-up (Open Molding) Fiber-Tech Inc.

Fiberglass Layup Technique The Epoxy Experts

Good Performance Epoxy Resin for Hand Lay-up Process