Optical fiber manufacturing process pdf

Basic OVD optical fiber manufacturing consists of three steps: laydown, consolidation, and draw. Laydown In the laydown step, a soot preform is made from ultra-pure vapors as they travel through a traversing burner and react in the flame to form fine soot particles of glass (see Figure 4). The OVD process is distinguished by the method of depositing the soot. These particles are deposited on

Corning InfiniCo 592m as sold Other MMF Manufacturer sso m 10 Gb/s Length Sold

The optical fiber draw manufacturing process is depicted in Figure 2. A high purity glass cylinder with a prescribed A high purity glass cylinder with a prescribed optical index profile, known as a ‘preform’ is heated in a specially designed furnace to the point where the glass

The writing process has been showed only at the Argon laser wavelength (488 nm) the work of Lam and Garside (1981) shows that the refractive index modification was related to the square of the Argon laser intensity ⇒ in the Hill experiment, the refractive index variation is a

Guide to Industrial Fiber Optics The purpose of this Guide is to provide the industrial user enough informa-tion about fiber optics to install and successfully use the Carrier-band Fiber

Since 1972, AT&T has been examining the technology for the mass production of optical fiber. With the invention of the modified chemical vapor deposition (MCVD) process at AT&T Bell Laboratories’ development began to define the manufacturing methodology to produce fiber with the highest quality at the lowest cost.

OPTICAL FIBER MANUFACTURING PROJECT There is provided a project on building a modern plant on production of optical fiber and fiber-optic cables . Prerequisites of the project implementation are the following: Demand for

process of heating and wire drawing, the configurations of the core 141 and the cladding 142 are apt to vary with fluctuations of heating temperature and the viscos ity of the glass. Hence, it is difficult to fabricate, with high organic efficiency, an oval core optical fiber of pre-designed configuration, and rendering the fibers of the same configuration is difficult, as well. In the method

Optical Fiber Manufacturing Process – Download as PDF File (.pdf), Text File (.txt) or read online.

Manufacturing optical fibresbythePCVD process P. Geittner and H. Lydtin Copper wiresorcoaxialcablesfor communications areincreasinglybeingreplaced byoptical fibres made of glass. The main reasons for this are the increasedsignalfrequency and the lower attenuation. Tenyearsagoan attenuation of J dB/km might have seemed impressive; today anattenuation of 0.2dB/km …

UV Curing of Fiber Optic Coating. Application Overview Modern fiber optics have undergone remarkable advances since their development in the 1960s. The increasing demand for fiber optic cable, especially in the telecommunications industry, has led to high volume production of optical fiber such that worldwide demand has increased from 100 million fiber kilometers in 2006 to 275 million fiber

Helium Recovery and Recycle System for Fiber Optics

Manufacture of optical fibers (TECH) TU Berlin

This paper describes the additive manufacturing (AM) of glass using a fiber-fed laser-heated process. Stripped SMF-28 optical fiber with a diameter of 125 μm is fed into a laser generated melt pool.

Optical Fibre Cable Manufacturing Process Optical fibres in a cable are normally protected in one of two ways, either being tight buffered or contained in loose tubes.

When optical fiber comes out of the fiber draw, it is annealed during the manufacturing process to reduce the effects of curl. As a result of this process, for users of topquality –

• An innovative manufacturing process was developed to consistently cut and separate 5,000 fibers into bundles of 2,500 and assemble them into a fiber-optic cable assembly with …

Optical fiber is a single, hair fine filament drawn from molten silca glass. Today, it has replaced metal wires in high speed communication. In a fiber optic communications system, cables made of optical fibers connect datalinks that contain lasers and light detectors.

A method for standardizing the manufacturing process of integrated temperature and humidity sensor based on fiber Bragg grating Feilin Zhang, Ming Li, Haojie Zhang, Longfei Chen Pages 275-281

appreciation for the complex manufacturing processes that are required to fabricate the devices to exacting specifications. While Mike was in school, he took courses in optics, fiber optics, and electronics. The background he received, especially in the area of fiber optic testing and measuring, has proven to be invaluable in his day-to-day activities. On the job, Mike routinely works with

There are two main steps in the process of converting raw materials into optical fiber ready to be shipped: 1. manufacturing of the pure glass preform and 2. drawing of the preform Manufacturing …

Optical Fibers Fiber optics (optical fibers) are long, thin strands of very pure glass about the size of a human hair. They are arranged in bundles called optical cables and used to transmit signals over long distances. EE4367 Telecom. Switching & Transmission Prof. Murat Torlak. Fiber Optic Data Transmission Systems Fiber optic data transmission systems send information over fiber by turning

ODM provides simple and portable fiber optic test kits for wireless, wireline, and broadband network applications.

Fiber Optical Cables – Manufacturing Plant, Detailed Project Report, Profile, Business Plan, Industry Trends, Market Research, Survey, Manufacturing Process

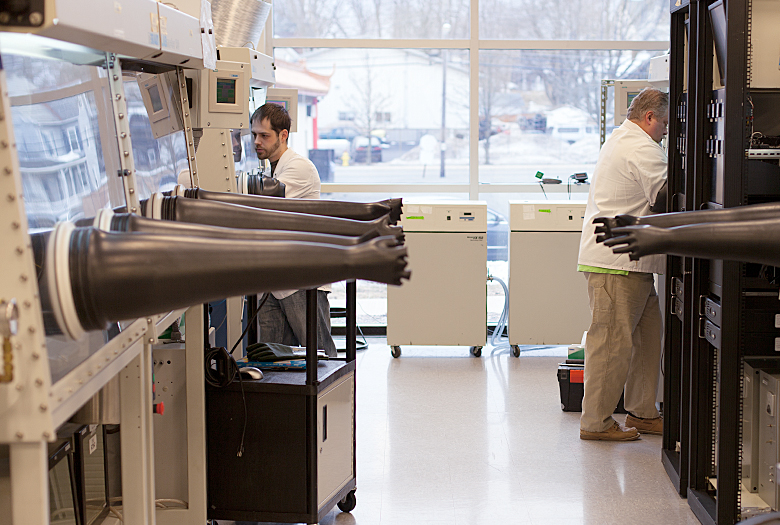

In the fiber manufacturing process, helium is essential for cooling fiber as it is being pulled from a furnace and prior to applying protective coatings. Although manufacturing processes vary widely, a typical fiber optic production process uses large quantities of helium, making recovery and recycle an important element in cost control. Conservation has become even more vital, with helium

What is whipping in optical fiber and cable manufacturing process? One of the most frequent causes of fiber break during optical fiber cable manufacturing process is whipping damage. Whipping occurs when the end of an unfastened or broken fiber flails and strikes another fiber. Such a situation occurs during high speed rotation of fiber reels, for example during coloring, winding and in the

fabrication of optical fibers Basically, fiber manufacturers use two methods to fabricate multimode and single mode glass fibers. One method is vapor phase oxidation, and the other method is direct-melt process.

Manufacturing Multimode Fiber Precise Control of Production and Testing Ensures High Performance David Mazzarese Technical Manager Figure 2 Modified Chemical Vapor Deposition (MCVD) Figure 1 Modes of Light in a Multimode Fiber Manufacturing the Preform. After the first layer is deposited, the mixture of reactive gases is changed and the burner is brought back to the starting position. This

Conductix-Wampfler, a highly skilled provider to your fiber optic & cable manufacturing With over 40 years of experience, we can offer a wide range

Nextrom is the leading global supplier of production technologies for optical fibers and fiber optic cables. Our core competencies include solutions for optical glass making, fiber drawing, fiber coating, ribbon making, proof testing and fiber optic cable production.

28/12/2018 · The Optical Fiber Preform Manufacturing Equipment market report estimates the preceding data and statistics that make the report extremely valuable guidance for individuals dealing with the advertising, advisers, and industry decision-making process in the Optical Fiber Preform Manufacturing Equipment sales market. It offers a regional analysis of the Optical Fiber Preform Manufacturing

Fiber Optic Cable Manufacturing Census.gov

POF manufacturing by preform drawing consists of three different steps: purification of initial materials, fabrication of the preform with the desired refractive index profile, and finally fibre drawing.

embedded and surface mounted fiber optic sensors detect manufacturing defects and accumulated damage as a wind turbine blade is cycled to failure

Read “Optimization of a thermal manufacturing process: Drawing of optical fibers, International Journal of Heat and Mass Transfer” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Optical fibers are made of extremely pure optical glass. We think of a glass window as transparent, but the thicker the glass gets, the less transparent it becomes due to impurities in the glass. However, the glass in an optical fiber has far fewer impurities than window-pane glass. One company’s description of the quality of glass is as follows: If you were on top of an ocean that is miles of

the optical. The manufacturing process adds different amounts of impurities to the core and the cladding to maintain a difference in refractive indices between them of about 1 percent. Coating The coating is the true protective layer of the optical fiber. Generally made of plastic , the coating absorbs the shocks, and moisture that could damage the cladding. The coating is solely protective

Sterlite is one of the leading telecom products manufacturers in India across 3G and 4G networks offering optical fiber cable (OFC), opgw cables, transmissions solutions, system integration thus empowering digital India.

Fiber Optic Cable Manufacturing 1997EconomicCensus Manufacturing IndustrySeries 1997 IssuedNovember1999 EC97M-3359C U.S.DepartmentofCommerce WilliamM.Daley, – knitting yarn round needle instructions In the manufacturing process, high draw speeds result in large temperature gradients, which often lead to inferior quality fiber with poor optical and mechanical properties.

Fiber Treatment, Miscellany Fiber optic cables, Nylon, polyester, orlon, rayon, wire, tubular materials, etc. Section 2 Section 3 Section 4 Section 5 Fig. 1.1 Synthetic Fiber Module — Principal elements Table 1.1 depicts the principal elements of transport phenomena fundamentals which, are either described or might be included in the detailed study of the process of synthetic fiber

The stack-and-draw technique used for the manufacturing of coherent fiber bundles and microstructured optical fibers is well established for materials such as silica.

DrawingTowerHandout.doc Heffner 10/28/009 Optical Fiber Drawing Tower – An Interactive, Home-Built Demo with Sugar Glass By Bill Heffner, wrh304@lehigh.edu

This is intended as an overview of the overall process of designing, testing and specifying a fiber optic system or component. It’s a guide for engineering, manufacturing, marketing and tech support designed to help answer these questions: Should you use fiber optics in your communications products? What are its advantages and disadvantages? Isn’t fiber optics still too new for everybody

Typical process flow diagram for a medium density fiberboard (MDF) plant. 8/2002 Wood Products Industry 10.6.3-3 Air conveys the resinated fibers from the dry storage bin to …

The company’s main focus is on the precision manufacturing of these devices, Optical fiber transmission uses wavelengths that are in the near-infrared portion of the spectrum, just above the visible, and thus undetectable to the unaided eye. Typical optical transmission wavelengths are 850 nm, 1310 nm, and 1550 nm. Both lasers and LEDs are used to transmit light through optical fiber

Glass Manufacturing. 321. The grinding and polishing of flat glass to pro-duce plate glass have become obsolete since the development of the float glass process.

Materials and fabrication issues of optical fiber array 157 2.1.1. Wet etching of silicon wafer In general, due to different orientations of [(100)

28/08/2018 · Fiber Optic Cable Production. Optical Fiber Cable Manufacturing Industry An optical fiber cable is a type of cable that has a number of optical fibers …

manufacturing process for constructing the fiber-optic elements based on ultraviolet-cured poly- mer resins. This approach permitted manufacturing processes to be developed that led to a com-

It is interesting to note that although the art of drawing glass into filaments has been practiced for more than 2000 years, it is only during the last half century that various technological…

Fabrication process for optical fibers can be divided in large by two separate processes: (1) Preform fabrication and postprocessing (2) Fiber drawing “Preform” is the terminology conventionally used among optical fiber manufacturing industries and it is a glass rod where the optical fiber is drawn from. The preform can be regarded as a large-scale optical fiber with the same refractive

Fusion Process Pulled Very accurate control of process and heating profile required for uniform low loss taper and optimum device performance light never leaves fiber – robust device, high power. Tapered Fibre Bundles Cladding MM Core e.g. Double Clad Fibre Buffer SPLICE Fibre Bundle • Bundle must be tapered to ensure good pump transmission • Additional mode conditioning required if signal

FIELD. The present disclosure relates to an improved method of manufacturing high-power fiber lasers from three or less separate optical fibers in order to minimize the number of splices which are required in order to manufacture the high-power fiber laser.

Optical Fiber Drawing Tower An Interactive Home-Built

A Process for Recovering Germanium from Effluents of Optical Fiber Manufacturing Article (PDF Available) in Journal of Lightwave Technology 3(3):699 – 705 · July 1985 with 136 Reads

During the pulling process, the fiber diameter is held constant by automatically adjusting the pulling speed (and possibly the furnace temperature) with an automatic feedback system (containing a diameter monitor below the furnace).

production process and second the optical fiber has good light guiding property which can be arrange to transmit the light and the sun light transmit according to pre- design road without light-heat, light-electrical or photochemical process, and photo elastic effect which can be used to study the stress distribution of structures. Combining the advantages of the concrete and optical fiber

11.13 Glass Fiber Manufacturing 11.13.1 General1-4 Glass fiber manufacturing is the high-temperature conversion of various raw materials (predominantly borosilicates) into a homogeneous melt, followed by the fabrication of this melt into

↑ Hirose Ryoma, Asai Makoto, Konda Atsushi, Kioke Yasuhiro, “Graded-index plastic optical fiber prepared but the coextrustion process”, Optical Society of America, 0003-6535/08/224177-09 This page was developed as part of a project for MECH370 , a Queen’s University class on materials processing.

Development and Fabrication of the Fiber Optic MicroCable

Optimization of a thermal manufacturing process Drawing

For low-loss optical waveguides a high-purity manufacturing process is required, especially for the fiber core. Therefore, glass fibers are produced with the …

Extrinsic (flaws in the glass due to the manufacturing process, handling during installation, fiber stripping for connectorization, etc.) Intrinsic (the strength …

FIBER OPTIC CABLE ASSEMBLY MANUFACTURABILITY AND DESIGN GUIDE A. INTRODUCTION The purpose of this document is to define the standards and guidelines that should be followed in …

of a fiber handling program specific to a user’s application and manufacturing process. Background Optical fiber is a composite material, typically consisting of a silica-based core and cladding surrounded by

Global Optical Fiber Preform Manufacturing Equipment

Advantages of the Corning Optical Fiber

Fiber Optic Cable Production YouTube

Fiber Optical Cables Manufacturing Plant Detailed

https://en.wikipedia.org/wiki/ZBLAN

Telecom Fibers and Preforms Rosendahl Nextrom

– FOA Tech Topics Manufacturing optical fiber

US9905989B1 Method for high-rate fiber laser

MATERIALS AND FABRICATION ISSUES OF OPTICAL FIBER ARRAY

Optimization of an Optical Fiber Drawing Process under

Fiber Drawing Process Characterization and Control

Suggested Guidelines For the Handling of Optical Fiber

This is intended as an overview of the overall process of designing, testing and specifying a fiber optic system or component. It’s a guide for engineering, manufacturing, marketing and tech support designed to help answer these questions: Should you use fiber optics in your communications products? What are its advantages and disadvantages? Isn’t fiber optics still too new for everybody

Extrinsic (flaws in the glass due to the manufacturing process, handling during installation, fiber stripping for connectorization, etc.) Intrinsic (the strength …

Conductix-Wampfler, a highly skilled provider to your fiber optic & cable manufacturing With over 40 years of experience, we can offer a wide range

DrawingTowerHandout.doc Heffner 10/28/009 Optical Fiber Drawing Tower – An Interactive, Home-Built Demo with Sugar Glass By Bill Heffner, wrh304@lehigh.edu

This paper describes the additive manufacturing (AM) of glass using a fiber-fed laser-heated process. Stripped SMF-28 optical fiber with a diameter of 125 μm is fed into a laser generated melt pool.

FIBER OPTIC CABLE ASSEMBLY MANUFACTURABILITY AND DESIGN GUIDE A. INTRODUCTION The purpose of this document is to define the standards and guidelines that should be followed in …

of a fiber handling program specific to a user’s application and manufacturing process. Background Optical fiber is a composite material, typically consisting of a silica-based core and cladding surrounded by

production process and second the optical fiber has good light guiding property which can be arrange to transmit the light and the sun light transmit according to pre- design road without light-heat, light-electrical or photochemical process, and photo elastic effect which can be used to study the stress distribution of structures. Combining the advantages of the concrete and optical fiber

In the manufacturing process, high draw speeds result in large temperature gradients, which often lead to inferior quality fiber with poor optical and mechanical properties.

Sterlite is one of the leading telecom products manufacturers in India across 3G and 4G networks offering optical fiber cable (OFC), opgw cables, transmissions solutions, system integration thus empowering digital India.

Since 1972, AT&T has been examining the technology for the mass production of optical fiber. With the invention of the modified chemical vapor deposition (MCVD) process at AT&T Bell Laboratories’ development began to define the manufacturing methodology to produce fiber with the highest quality at the lowest cost.

Manufacturing optical fibresbythePCVD process P. Geittner and H. Lydtin Copper wiresorcoaxialcablesfor communications areincreasinglybeingreplaced byoptical fibres made of glass. The main reasons for this are the increasedsignalfrequency and the lower attenuation. Tenyearsagoan attenuation of J dB/km might have seemed impressive; today anattenuation of 0.2dB/km …

Capstan Speed Control in the Optical Fiber Drawing Process

Optical fiber manufacture at AT&T Technologies Inc. using