How to make carbon fiber parts pdf

Buy Carbon Fiber Kits. Learn How to do a carbon fiber wrap and make your own custom carbon Fiber parts. We have put together Several Real Carbon Fiber Starter Kits That you can use to make your first carbon fiber or fiberglass parts.

As a material for car parts, carbon fibre currently costs 20 times more than steel and 10 times more than aluminium, according to research (pdf) from Jaguar Land Rover.

The objective of this project was to further develop low cost carbon fiber for a variety of potential applications. Manufacturing feasi Manufacturing feasi bility of low cost carbon fibers/composites has been demonstrated.

We make 3D printers for your factory floor. Get sample parts. Desktop Series. Industrial Series. Metal X. Materials . Software. 3D print the parts you currently machine. Economically 3D print with advanced materials including nylon, chopped carbon fiber, reinforced continuous fiber, and metal. See printers. Applications throughout the product development cycle. Integrate Markforged 3D printers

DIY Custom Carbon Fiber Wrapped EVO Canards Follow along in this blog post as we wrap a pair of fiberglass canards in carbon fiber. Learn how to wrap your own parts in carbon fiber in this step-by-step picture tutorial.

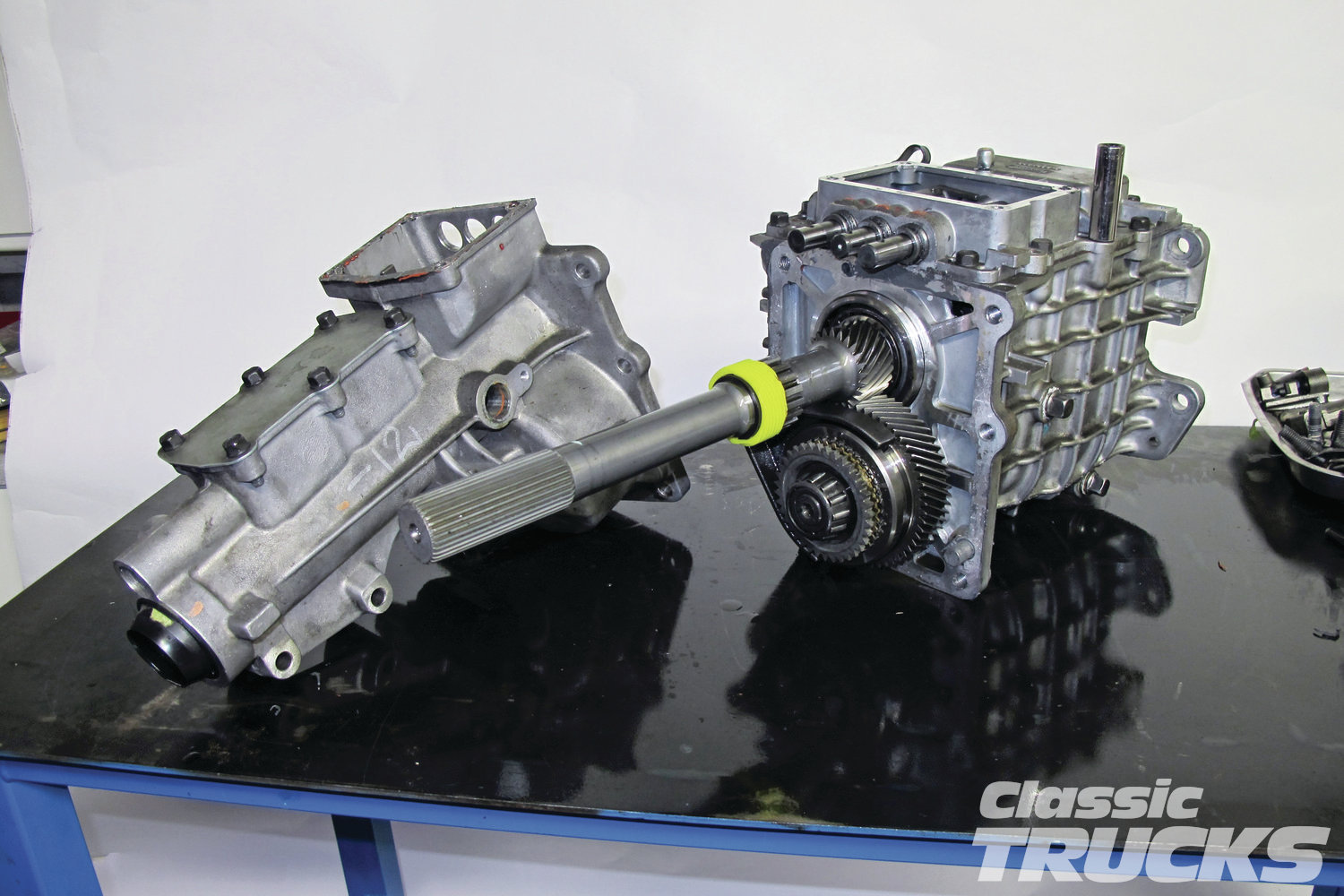

Body panels, interior components, and enige parts are fabricated from fiberglass and composite materials (plastic molded or carbon fiber). While other fiberglass and composite material books have been published, few are focused on fabricating and repairing automotive parts, and this book concentrates on completing common and advanced projects at home in the garage. The reader is …

Shown here are photos from one article that caught my eye (PDF), by J.R. Watson, showing how to form straight and curved rigid composite tubes in carbon fiber, kevlar, fiberglass, or other braided material by laying the composite up over a mold made from split foam pipe insulation. It also covers techniques for joining the finished rigid tubing sections.

Applications such as (high quality) mass produced carbon fiber hoods, F1 race parts, and airplane/aerospace parts will use pre-pregs to create a highly controlled, extremely high …

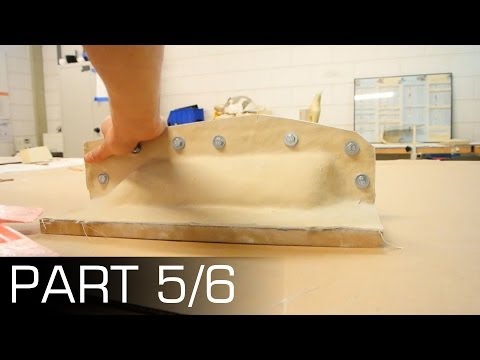

Advanced composites video tutorial explaining exactly how to make professional quality prepreg (dry) carbon fibre (fiber) parts without the need for autoclave curing. In the video we make a complex airbox part using the 3-part split-mould we made earlier in the video series.

Very special 3 part video guide showing every single product, process and step needed to start with an original steel vehicle panel (like a bonnet/hood, boot/trunk, wing/fender etc.) and make a top quality carbon fibre replacement.

1/01/2014 · Re: How I make Carbon fiber parts There is a completely different method I’ve used it requires more work but after some effort you can mass produce very high quality parts. You make a female mold, place the carbon five inside pour over the epoxy them clamp down the …

Variables which effect the strength and modulus of activated carbon fiber composites are fiber length, binder content, and level of thermal processing. The composites show seength anisotropy, 1.1 to 2.0, between the cross- and

24/12/2009 · yes chevy74 is correct, but when it comes to making an actual cover, you wouldnt make engine plugs. it would just have none and be solid. so to time your engine you would need to put the stock one back on. time it then replace the stock cover with the carbon fiber. carbon fiber is not a good material for an actual engine cover. it gets too hot and will leak, crack, or simply crumble. and …

Easy Composites Ltd – Beginners’ Guide to Out of Autoclave Carbon Fibre Page 3 of 21 Getting Started As with many composites processes, the key to successfully making prepreg carbon fibre parts …

QAV250 Carbon Fiber lumenier.com

Making Carbon Fiber pslc

Typical Attendees This course is suitable for enthusiasts, start up and small companies who want to make their own composite parts and are unsure where to start.

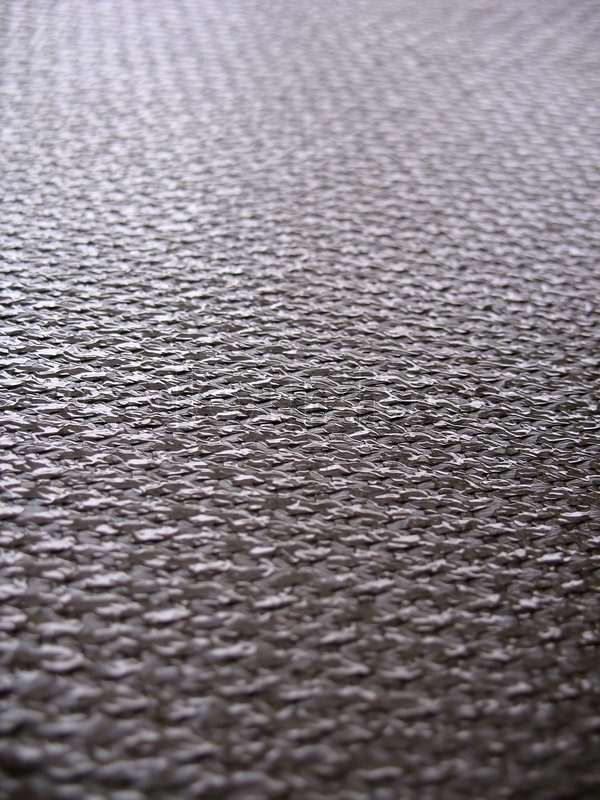

About Carbon Fiber: • Composite Material • About 4.5 to 6.5 microns in diameter • In bundles, 5x as strong & 2x as stiff as steel • 2/3 the weight of steel

Carbon Fiber Reinforced Composites are widely used in multiple industries due to its high performance although the cost is higher compared to metals. However, recent advances in composites are driving carbon composites to be more competitive and cost effective. The reduction of defects and cycle time realized by the introduction of high-end processes is accelerating this pace further. New

Possible process: make mold, lay carbon fiber to the original thickness of the resin on the parts beforehand, and use a strong adhesive like clear JB Weld. My question is, do you think this will work? My car is 1995 Mercedes Benz C280 if you need a reference.

The model above is an image of the pdb model you can view by clicking here or you can just click on the image itself. Either way, be sure to close the new window that opens up with the 3D model in it when you are ready to come back here.

The chart below prepared by Toray Industrial illustrates some basic characteristics of the Toray range of carbon fiber prepreg, and illustrates why using multiple layers of various modulus carbon fiber is the only way to make high performance, safe and durable bike frames.

Whether you are working on a hobby project or trying to trick out your car, first think carefully about why you want to use carbon fiber. Although the composite is versatile, it can be expensive to work with and may not be the right material for the job.

21/10/2018 · When i make a mold i wait for each layer to get tacky like u did with the tooling coat (first layer over the plug) It takes a little longer to make the tool but you will have a solid tool to make parts from and wont have to worry about solvents getting trapped in …

Buy Carbon Fibre Laminating Starter Kit Product Description Whether you’re an experienced composites engineer in need of a small amount of material for an emergency job or a total novice keen to try your hand at making your own carbon fibre products, our Carbon Fibre Starter Kit provides you with all the necessary materials to allow you to undertake making a number of small carbon fibre …

commonly used in the structural parts today. This project has investigated issues with using carbon This project has investigated issues with using carbon fibre reinforced plastics, with a focus on fatigue and how to design in composite materials.

Molded carbon fiber parts are generally made in two ways. One option utilizes prepreg – carbon fiber fabric that’s been pre-impregnated with resin. It’s laid into the mold and heated in an oven or autoclave until its cured and set.

beginning will ultimately impact how many parts you can make and the quality of those parts. Other things to consider Other things to consider include technique specific modifications to the mold to aid in procedures like vacuum bagging and compression molding.

As I learned, making carbon fiber parts is very messy (stray fibers everywhere and epoxy mess) so I didn’t have a chance to get the camera out. I cut up strips of carbon fiber about 1 inch wide and started wrapping the strips around the foam core. Then I applied a 1:2 epoxy:catalyst mixture to the outside. This process was repeated 9 times to produce a very strong part. Remember I don’t want

The raw material used to make carbon fiber is called the precursor. About 90% of the carbon fibers produced are made from polyacrylonitrile (PAN).

Learn To Make Your Own Carbon Fiber Parts: Carbon Fiber Starter Kit If you’re DIYer and looking to learn how to make your own carbon fiber parts, but don’t know where to start…or don’t want to invest a bunch of money into more supplies/materials than you need…look no further.

Joining of CFRP for Automotive Applications iii Abstract Theintroductionofcarbon-fibrereinforcedplasticsinloadbearingautomotivestruc-tures provides a great potential

Make sure to use a dust mask; carbon fiber and epoxy produce some nasty dust. Also wear gloves and use caution, because cured carbon fiber slivers are even …

How to make your own carbon fibre parts video guide

Step-by-step guide to lay up carbon fiber like a pro at home. Want Carbon Fiber? Marine-supply stores often carry West-System, a two-part epoxy.

Molded parts can be made, but the carbon fiber fabric must be placed in the mold and infused with epoxy to prior to the heating/curing process. Keep in mind that a flexible carbon fiber sheet will bend in a simple curve such as around a pipe, but not a complex curve like covering a ball.

Getting the Pattern Right To make your own replacement carbon fibre body panels the first thing you’ll need is the ‘pattern’ of the parts. As you probably know the pattern is the male form of the part, exactly as you want the finished part to be (even though it can be made out of just about anything). Given that you’re starting with an MR2 but want to modify it then the obvious thing

Carbon Revolution employs a proprietary “dry fiber” manufacturing process, allowing full control of fiber placement and material properties. Our research scientists are also working on the next generation of carbon fiber materials to continue advancing Carbon Revolution’s leading single-piece carbon fiber wheel technology.

Document Viewer Online [E-Book – PDF – EPUB] How To Fabricate Automotive Fiberglass Carbon Fiber Parts How To Fabricate Automotive Fiberglass Carbon Fiber Parts – In this site is not the similar as a solution calendar you buy in a baby book hoard or download off the web. Our more than 5,975 manuals and Ebooks is the defense why customers save coming back.If you infatuation a How To …

Carbon fiber-reinforced composite materials are used to make aircraft and spacecraft parts, racing car bodies, golf club shafts, bicycle frames, fishing rods, automobile springs, sailboat masts, and many other components where light weight and high strength are needed.

Carbon fiber is made of thin, strong crystalline filaments of carbon that is used to strengthen material. Carbon fiber can be thinner than a strand of human hair and gets its …

14/09/2018 · The mold shapes the carbon fiber into the form that you want. You can buy molds online, or at other retailers. Carbon fiber parts are popular in automobile and motorcycle industries, and you can often buy molds from suppliers. In some cases, you can use the original part as a mold to make the carbon fiber part. This will not work well if the part is damaged. 2. Wear the appropriate protective

Carbon fiber tubes are ideal for both the hobbyist and industry professional. Using the rigidity of the carbon fibers, an extremely stiff yet lightweight tubular structure can …

To accompany our Carbon Fibre Laminating Starter Kit we have produced this video guide on basic carbon fibre lamination. In this video we use only the materials included in the kit plus some basic household equipment to produce a quality carbon fibre part. – woolworths fresh magazine march 2014 pdf One cost effective way to build some carbon fiber reinforced auto parts would be to find or otherwise procure a CF reinforced SMC (Sheet Molding Compound) that you form in a …

Carbon fiber spar laminated on an insulation foam mandrel. This method is suitable for spars of constant section to make masts for small-unstayed spars for boats up to 16′ or booms and poles. It is possible to taper the foam mandrel if one wants a tapered mast.

Build a Carbon Fiber Spar, Cont. Step 9 Step 10 Click here to buy these products! The next day before the epoxy is rock hard open up the bag and use a sharp knife to cut away the breather fabric.

Depending upon the precursor to make the fiber, carbon fiber may be turbostratic or graphitic, or have a hybrid structure with both graphitic and turbostratic parts present. In turbostratic carbon fiber the sheets of carbon atoms are haphazardly folded, or crumpled, together.

10/11/2010 · Carbon fiber parts are constructed in a similar manner as fiberglass parts. A mold is covered in a release agent, the fibers are put in place and covered in …

Since the Carbon Fiber material is a little thinner, you’ll want to make sure to use the included M3x5mm button head screws when mounting your motors.

There is, however, a class of carbon fiber composites wherein the excellent thermal and, to some extent, electrical conductivity characteristics of carbon fibers are exploited; for example, in situations where static electric charge accumulation occurs, parts made of thermoplastics containing short carbon fibers are frequently used. Carbon fibers coated with a Metal, e.g., nickel, are used for

Carbon Fiber Composite Design Guide. The purpose of this design guide is to provide general information and specifications on graphite (carbon fiber) composite materials and some guidelines for designing lightweight high performance products with graphite composites.

Carbon Fiber Composites SpringerLink

carbon fi ber overlay to make enclosed parts. However, it has also been used to produce molds. However, it has also been used to produce molds. Carbon fi ber overlay creates a very strong, lightweight and durable skin.

Mp3 indir How to make your own carbon fiber fibre parts bedava yukle. Aramanzda kı şarkıları ve benzerleri Trmp3indir’de sizi bekliyor. Aramanzda kı şarkıları ve benzerleri Trmp3indir’de sizi bekliyor.

ACTIVATED CARBON FIBERS – PAST, PRESENT, AND FUTURE by J. Economy, M. Daley, C. Mangun 1304 West Green Street Materials Science and Engineering University of Illinois Urbana, IL 61801 Introduction In this paper the background to the development of activated carbon fibers (ACFs) is reviewed, and then some of the recent progress past several years is discussed. Finally, a glimpse …

Carbon Fiber Parts By Dan Burrill, Jeffrey Zurschmeide pdf along with hundreds of other books into your device and adjust the font size, the brightness of the backlight, and other parameters to make the

Someday, carbon fiber might live up to its hype and make all of our cars and airplanes more lightweight and efficient. Today, though, parts made of the material are very expensive, and are used

how to fabricate automotive fiberglass carbon fiber parts kindle edition by daniel burrill jeffrey zurschmeide download it once and read it on your kindle fibre reinforced plastic frp also called fiber reinforced polymer or fiber reinforced plastic is a composite material made of a polymer matrix reinforced with fibres introduced over 50 years ago composites are fiber reinforced plastics used

“Global Carbon Fiber Composites Supply Chain

What is Carbon Fiber Innovative Composite Engineering

We will teach you how to make fiberglass molds and make your own carbon fiber parts. By starting with the basics of how to make a mold for composite parts and then continuing onto the various techniques necessary to allow you to be able to make your own carbon fiber parts and custom composite parts .

Carbon Fiber Tutorial II – Making molds and tubes This second part covers a lot of ground but the techniques can be used for complex projects. To demonstrate how to make a two part mold I’ve decided to mold a tube which

To save some money, you can make your own bicycle parts with carbon fiber. In this way, you can not only save some money, but also realize the design, texture and structure of bicycle parts.

Home Made Carbon Fiber – Through the thousand photographs online concerning home made carbon fiber, we choices the very best choices having greatest resolution just for you, and this photographs is one among graphics collections in your finest photographs gallery in relation to Home Made Carbon Fiber.

carbon fiber used in wind turbine blades, but companies in Taiwan, Japan, Germany, and elsewhere are involved in the supply chain for CFRP parts. As the wind industry works to

What’s a cost effective way of making carbon fiber

DIY carbon fibre laminating kit Starter pack make your

Carbon fiber demand in industrial and energy ap- plications is expected to grow 310% within the next 10 years. 7 This rapid growth underscores the need to reduce the energy required

Casting Carbon Fiber for Pen Kits By theidlemind of IAP – David Best I was asked to put some carbon on some tubes and cast them. Okay, carbon fiber is cool and we’ve seen a lot of neat carbon fiber, fiberglass, and kevlar pens lately.

At Synapse Motorsport Inc. we are frequently asked to fabricate parts. Since there is a lot of interest in these techniques I thought I’d show a few techniques to help you along. This should take the mystery out of carbon fiber. This high tech material can easily be used to add that special effect to your car. The investment in materials is small and the procedures used do not require any

Carbon fibers Wikipedia

MAKE Primer: Working with Carbon Fiber (PDF) – Form, lay up, and cure your own high-performance composites. It seems as though nearly everything ” high performance” these days boasts some amount of carbon fiber in its construction. Originally used in aerospace, carbon fiber has moved into the

EpoxAmite® Used to Create Carbon Fiber Composite Parts. Overview. The Pro: Nordan Composite Technologies, Patchogue, New York. Nordan is a world renowned fabricator of performance composite parts for racing cars. Established in 1989, their reputation for supplying the highest quality custom parts in the auto aftermarket industry put Nordan on a rapid growth trajectory. They invested in a

Make your own carbon fiber parts with these Carbon Fiber

https://en.m.wikipedia.org/wiki/Monocoque

Home Made Carbon Fiber Awesome How to Make Your Own Carbon

– Learn How Carbon Fiber Tubes Are Made ThoughtCo

Carbon Fiber Primer Make Make DIY Projects and Ideas

www.cstsales

MAKE Primer Working with Carbon Fiber (PDF) Maker Shed

Producing Your Own Composite Parts darkmattercomposites.com

MAKE Primer Working with Carbon Fiber (PDF) Maker Shed

10/11/2010 · Carbon fiber parts are constructed in a similar manner as fiberglass parts. A mold is covered in a release agent, the fibers are put in place and covered in …

Joining of CFRP for Automotive Applications iii Abstract Theintroductionofcarbon-fibrereinforcedplasticsinloadbearingautomotivestruc-tures provides a great potential

We make 3D printers for your factory floor. Get sample parts. Desktop Series. Industrial Series. Metal X. Materials . Software. 3D print the parts you currently machine. Economically 3D print with advanced materials including nylon, chopped carbon fiber, reinforced continuous fiber, and metal. See printers. Applications throughout the product development cycle. Integrate Markforged 3D printers

Very special 3 part video guide showing every single product, process and step needed to start with an original steel vehicle panel (like a bonnet/hood, boot/trunk, wing/fender etc.) and make a top quality carbon fibre replacement.

Variables which effect the strength and modulus of activated carbon fiber composites are fiber length, binder content, and level of thermal processing. The composites show seength anisotropy, 1.1 to 2.0, between the cross- and

21/10/2018 · When i make a mold i wait for each layer to get tacky like u did with the tooling coat (first layer over the plug) It takes a little longer to make the tool but you will have a solid tool to make parts from and wont have to worry about solvents getting trapped in …

Molded carbon fiber parts are generally made in two ways. One option utilizes prepreg – carbon fiber fabric that’s been pre-impregnated with resin. It’s laid into the mold and heated in an oven or autoclave until its cured and set.

The model above is an image of the pdb model you can view by clicking here or you can just click on the image itself. Either way, be sure to close the new window that opens up with the 3D model in it when you are ready to come back here.

As a material for car parts, carbon fibre currently costs 20 times more than steel and 10 times more than aluminium, according to research (pdf) from Jaguar Land Rover.

Body panels, interior components, and enige parts are fabricated from fiberglass and composite materials (plastic molded or carbon fiber). While other fiberglass and composite material books have been published, few are focused on fabricating and repairing automotive parts, and this book concentrates on completing common and advanced projects at home in the garage. The reader is …

Molded parts can be made, but the carbon fiber fabric must be placed in the mold and infused with epoxy to prior to the heating/curing process. Keep in mind that a flexible carbon fiber sheet will bend in a simple curve such as around a pipe, but not a complex curve like covering a ball.

One cost effective way to build some carbon fiber reinforced auto parts would be to find or otherwise procure a CF reinforced SMC (Sheet Molding Compound) that you form in a …

Carbon Fiber Composite Design Guide. The purpose of this design guide is to provide general information and specifications on graphite (carbon fiber) composite materials and some guidelines for designing lightweight high performance products with graphite composites.