Electrospinning of nanofibers reinventing the wheel pdf

Among the most successful methods for producing nanofibers such as chemical reduction, layer-by-layer self-assembly, and template-based techniques, electrospinning has attracted much attention since it is one of the most simple, versatile, and low-cost methods for generating nanofibers from a wide range of materials including polymers, composites, ceramics, and semiconductors [7, 11–14]. It

Chitin nanofibers are prepared from the exoskeletons of crabs and prawns, squid pens and mushrooms by a simple mechanical treatment after a series of purification steps. The nanofibers have fine nanofiber networks with a uniform width of approximately 10 nm. The method used for chitin-nanofiber

electrospinning chamber for the synthesis of metal oxide nanofibers. REFERENCES SYNTHESIS OF ELECTROSPUN NANOFIBERS ADSORPTIVE CATALYSIS IN A FIXED BED REACTOR 1. Metal oxide fibers and powders are respectively packed inside a fixed bed reactor. 2. Sulfides (H 2 S) are fed through last four inlet streams to the reactor in a flow rig. 3. Streams of H 2 S reach the reactor bed …

Abstract Polyacrylonitrile nanofibers containing different amounts of gold nanoparticles have been prepared by electrospinning technique. By using the gold nanoparticles as seeds, thin continuous gold films have been deposited on the surface of polyacrylonitrile fibers through self-catalyzed reduction of chloroauric acid in solution. The conductivities of the fibrous mats increase with the

PDF Secondary surface texture is of great significance to morphological variety and further expands the application areas of electrospun nanofibers. This paper presents the possibility of

Basics of electrospinning Electrospinning is a fascinating technique for making continuous and very thin fibers from a variety of polymers and it even allows …

Electrospinning of nanofibers: Reinventing the wheel?. Advanced Materials , 16: 1151 – 1170 . [Crossref] , [Web of Science ®] [Google Scholar] ), and electrospun nanofibers have shown excellent porous properties and vast application potential in diverse areas (Agarwal & Wendorffa, 2008 Agarwal, S. and Wendorffa, J.H. 2008 .

Nowadays, thanks to the electrospinning process, polymeric fibers in nanoscale diameters (10–500 nm) are easily producible. During the last decade, the electrospinning technique has been greatly investigated and developed. One of the most important fields of study on the electrospinning process is the influence of effective parameters on

Hybrid nanofibers with different concentrations of multi-walled carbon nanotubes (MWCNTs) in polyacrylonitrile (PAN) were fabricated using the electrospinning technique and …

Electrospun Nafion® Nanofibers for Proton Exchange Membranes Michael W. Cason Literature Seminar September 23, 2010 Electrospinning has gained significant attention in the past two decades as a

Electrospinning provides an effective method for generating nanofibers from solution of carboxymethyl chitosan/polyoxyethylene oxide (CMCS/PEO). The goal of this work is to explore the potential application of electrospun CMCS/PEO nanofiber membrane in fruit fresh-keeping. The microstructure, antibacterial activity, hydrophilia, and air

Download reinventing the wheel or read online books in PDF, EPUB, Tuebl, and Mobi Format. Click Download or Read Online button to get reinventing the wheel book now. This site is like a library, Use search box in the widget to get ebook that you want.

Furthermore, clinical application of electrospun nanofibers including wound healing, tissue regeneration, drug delivery and stem cell therapy are highly feasible due to the ease and flexibility of fabrication of making nanofiber with this cost-effective method using electrospinning. In this review, we have highlighted the current state of the art and provided future perspectives on electrospun

Polymeric nanofiber non-woven materials produced by electrospinning have extremely high surface-to-mass (or volume) ratio and a porous structure with excellent pore-interconnectivity. These characteristics plus the functionalities and surface chemistry of the polymer itself impart the nanofibers

Electrospinning of polyacrylonitrile was used to investigate the effect of horizontal vs. vertical fiber deposition methods and operating variables on the degree of nanofiber alignment. A high-speed camera and Fiji image analysis software were used to assess differences and changes in the degree of fiber parallelism, allowing for effective

Electrospinning has the ability to produce nanofibers within 100-500 nm. Some applications require certain fiber diameter. As a relatively new process, there are many electrospinning parameters that are believed to influence the nanofibers diameter. The purpose of this review is to identify and discuss the effect of some of those parameters, i.e. concentration, spinning distance, and applied

Electrospinning is a simple technique to produce polymer nanofibers having special sensing property with the added advantages of nanostructures.

Electrospinning of nanofibers is one fabricat ion method that has gained popularity over the last decade. It is a simple approach that provides exceptional …

Structural and electrical properties of single Ga/ZnO

Continuous Polymer Nanofibers Using Electrospinning

The aim of this study was to investigate the feasibility of assembling small diameter tubes with helically arranged fibres tomimic the helical structure of native blood vessels for possible future vascular tissue engineering applications.

Rotational dynamics of optically trapped nanofibers Antonio Alvaro Ranha Neves,1,* Andrea Camposeo,1 Stefano Pagliara,2 Rosalba Saija,3 Ferdinando Borghese,3 Paolo Denti,3 Maria Antonia Iatì,4 Roberto Cingolani,1 Onofrio

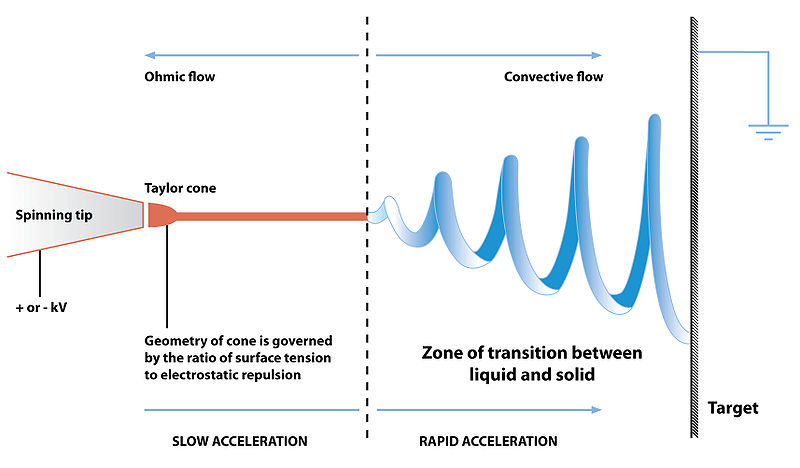

Electrospinning uses an electrical charge to draw very fine (typically on the micro or nano scale) fibres from a liquid. Electrospinning shares characteristics of both electrospraying and conventional solution dry spinning [1] of fibers.

An electrospinning process is used to create polymer-based nanofibers with diameters ranging from 10-180 nm and lengths of up to several centimeters. By controlling the electrostatic field and the

Nanofibers produced from electrospinning have a naturally formed porous structure with excellent pore interconnectivity and the pores are in the range between tens of nanometers to a few micrometers.

Electrospinning of nanofibers is one fabrication method that has gained popularity over the last decade. It is a simple approach that provides exceptional …

American Journal of Medical Genetics 45694-695 (1993) Letter to the Editor Reinventing the Wheel To the Editor: Chapmanâs [19921 editorial comments on the experi- ences…

Abstract. Alumina nanofibers were prepared by a technique that combined the sol–gel and electrospinning methods. The solution to be electrospun was prepared by mixing aluminum isopropoxide (AIP) in ethanol, which was then refluxed in the presence of an acid catalyst and polyvinylpyrolidone (PVP) in ethanol.

Electrospinning of Nanofibers: Reinventing the Wheel?** By Dan Li and Younan Xia* Electrospinning provides a simple and versatile method for generating ultrathin fibers from a rich variety of materials that include polymers, composites, and ceramics. This article presents an overview of this technique, with focus on progress achieved in the last three years. After a brief description of the

27/02/2013 · Electrospinning of Nanofibers: Reinventing the Wheel?.” J.wiley.* and Constantine.Qi. Xuliang Deng. Y. Jing. Horst A. Xiabin. X.1002/adem. 2. Dalton. “Co-electrospinning of Core-Shell Fibers Using a Single-Nozzle Technique.3 Lixin Yang.doi. These scaffolds fulfill a similar purpose as the extracellular matrix in natural tissue. This would introduce multi-functionality (flame. ^ Alexander

Fabrication of Biodegradable PCL Particles as well as PA66 Nanofibers via Air-Sealed Centrifuge Electrospinning (ASCES) Article 3, Volume 4, Issue 1, Winter and Spring 2015, Page 15-19 PDF …

Abstract. Electrospinning provides a simple and versatile method for generating ultrathin fibers from a rich variety of materials that include polymers, composites, and ceramics.

Abstract 10.1002/adma.200400719.abs Electrospinning provides a simple and versatile method for generating ultrathin fibers from a rich variety of materials that include polymers, composites, and ceramics. This article presents an overview of this technique, with focus on progress achieved in the last three years. After a brief description of the setups for electrospinning, we choose to

Alumina nanofibers were prepared by a technique that combined the sol–gel and electrospinning methods. The solution to be electrospun was prepared by mixing aluminum isopropoxide (AIP) in ethanol, which was then refluxed in the presence of an acid catalyst and polyvinylpyrolidone (PVP) in …

1.Li D, Xia Y. Electrospinning of nanofibers: reinventing the wheel? Advanced Materials, 2004;16 (14):1151-1170. 2.Ondarcuhu T, Joachim C. Drawing a single nanofibre over hundreds of microns.

Electrospinning is a process by which a charged liquid polymer solution is introduced into an electric field. The liquid polymer solution is dispensed via a needle attached to a syringe at a voltage between 10-20kV and is deposited on a conductive material at ground (0V) located between 10-30cm from the needle location. The polymer is ejected from a needle with an inner diameter (ID) between

Electrospinning; Grooved nanofibers; Polystyrene; Solvent systems – Background Electrospinning is a versatile nanofiber production technique using electrical force to stretch a charged polymer solution jet coupled with solvent evaporation and subsequent harvesting of solidified or semi-solidified nanofibers [1, 2]. Electrospun nanofibers are gaining increasing attention due to their distinct

The mixture of the cell and the salt solution) on nanofibers surface increases attraction power of the cell b( e- cause of salt and there may be some porosity as well on …

The parameters of electrospinning polyvinylalcohol (PVA) of different molecular weights using spiral disk spinnerets were explored. Ethylene-propylene side-by-side (ES) nonwoven was used as the substrate. Electrospun PVA/ES composite membranes were fabricated by laminating a nanofiber web onto the nonwoven substrate via the hot-press method.

Technote: Electrospinning Carbon Fibers for Multiscale Fuel Cell Support Electrodes Sean White, Department of Mechanical Engineering, Columbia University

This paper reports the development and characterization of PZT nanofibers with average diameters ranged from 50 to 150 nm for various sensing and actuation applications.

Abstract. The critical parameters determining the electrospinning of silica nanofibers starting from tetraethoxysilane sols are reported. By controlling the reaction conditions, the rheological properties of the sol allowed for electrospinning without needing the addition of an organic polymer.

Abstract. BaFe12O19 single-particle-chainud nanofibers have been successfully prepared byud an electrospinning method and calcinationud process, and their morphology, chemistry,ud and crystal structure have been characterizedud at the nanoscale.

Alumina nanofibers were prepared by a technique that combined the sol-gel and electrospinning methods. The solution to be electrospun was prepared by mixing aluminum isopropoxide (AIP) in ethanol, which was then refluxed in the presence of an acid catalyst and polyvinylpyrolidone (PVP) in …

Reinventing the wheel [PDF Document]

Read “Effects of electrospinning parameters on titanium dioxide nanofibers diameter and morphology: An investigation by Box–Wilson central composite design (CCD), Chemical Engineering Journal” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips.

Electrospinning was carried out using continuous equipment in which a horizontal electric field was generated between a nozzle system and a collector plate, and a web having a width of 300 mm was conveyed past the front side of the collector.

In this study, nanofibers of polyurethane and thermoplastic polyurethane were produced by electrospinning method and the average diameters of the produced nanofibers were analyzed by the scanning electron microscopy.

Electrospinning has been recognized as an efficient technique for the forming of polymer nanofibers. Silk fibroin (SF) nanofibers were electrospun from SF solution using trifluoroacetic acid – wooldridge econometrics solutions manual pdf Random and highly aligned bead-free chitosan nanofibers (NFs) were successfully prepared via electrospinning by keeping the applied voltage (22 kV), f…

Electrospinning is a process of nanofibers production by high electrical field known since the beginning of the former century [1, 2]. It is a popular technology for …

Electrospinning is a popular technique to produce structures in the form of nanofibers. These nanofibers can be used for many applications such as filtration …

Electrospun fibers are explored as a new system for controlled drug delivery. Novel techniques capable of obtaining polymer nanofibers have been reported in the literature. They include solution blow spinning (SBS), which is a technique to produce polymer nanofibers in the same range as electrospinning, using pressurized gas instead of high

Electrospinning Of Nanofibers Reinventing The Wheel Pdf Download – http://shorl.com/visulotoryjy

Electrospinning is the most commonly used method to generate nanofibers because of the straightforward setup, the ability to mass-produce continuous nanofibers from various polymers, and the capability to generate ultrathin fibers with controllable diameters, compositions, and orientations.

Li, D. and Xia, Y.N. (2004) Electro-Spinning of Nanofibers: Reinventing the Wheel. Advanced Materials. (2009) Laboration Work at Swerea IVF (Supervisor-Anna Thorvaldsson). 5 March 2009, M. Sc in Textile Technology Program at University of Boras, Textile Fiber Material

Electrospinning is a fiber production method which uses electric force to draw charged threads of polymer solutions or polymer melts up to fiber diameters in the order of some hundred nanometers.

D. Li and Y. Xia, “Electrospinning of Nanofibers Reinventing the Wheel” Advanced Materials, Vol. 16, No. 14, 2004, pp. 1151-1170. doi10.1002/adma.200400719

1: Brandon WP. Reinventing American Health Care: How the Affordable Care Act Will Improve Our Terribly Complex, Blatantly Unjust, Outrageously Expensive, Grossly

9/04/2013 · Electrospinning is a popular technique to fabricate tissue engineering scaffolds due to the exceptional tunability of fiber morphology that can be used to control scaffold mechanical properties, degradation rate, and cell behavior.

Silver ions have been widely used in various biomedical fields such as wound dressing materials, body wall repairs, augmentation devices, tissue engineering scaffolds, in this study, we prepared

BaFe12O19 single-particle-chainud nanofibers CORE

A novel method for the electrospinning of multiple polymer jets into nanofibres is presented. In this work, 20 wt% nylon 6 solution was electrified and pushed by air pressure through the walls of

Polyvinylidene fluoride (PVDF) is one of the most studied polymer systems that exhibits piezoelectric, pyroelectric, and ferroelectric properties.

Electrospinning of nanofibers reinventing the wheel. (2010). Electrospun collagen–chitosan nanofiber: A biomimetic extracellular matrix for endothelial cell and smooth muscle cell.

The analysis based on 3D simulation of the electric field could benefit further development of needleless electrospinning in which the production rate and quality of as-spun nanofibers are of great importance.

Nanofibers (NFs) of Ga-doped ZnO (GZO) were prepared by electrospinning of polymer–salts solution. Sintering profiles reported in the literature led to loss of the fibrous structure.

Read “Electrospinning jets and polymer nanofibers, Polymer” on DeepDyve, the largest online rental service for scholarly research with thousands of academic publications available at your fingertips. In electrospinning, polymer nanofibers are formed by the creation and elongation of an electrified fluid jet.

Sayed Reza Hosseini, Shahram Ghasemi and Mina Kamali-Rousta, Preparation of CuO/NiO composite nanofibers by electrospinning and their application for electro-catalytic oxidation of hydrazine, Journal of Power Sources, 343, (467), (2017).

Fabrication of polyurethane and thermoplastic polyurethane

In situ synthesis of gold nanoparticles on porous

Electrospinning and Electrospun Nanofibers scirp.org

Effects of electrospinning parameters on titanium dioxide

(PDF) Electrospinning of Grooved Polystyrene Fibers

THE SLIT NEEDLELESS ELECTRODE FOR THE ELECTROSPINNING

Dr. Daniel Bullock Department of Electrical Engineering

wooldridge 6th edition solution manual – Application and Synthesis of Electrospun Nanofibers for

Characterization and application of electrospun alumina

Electrospinning of Continuous Nanofiber Bundles and

Highly aligned narrow diameter chitosan electrospun

reinventing the wheel Download eBook pdf epub tuebl mobi

Dr. Daniel Bullock Department of Electrical Engineering

Electrospinning of Nanofibers: Reinventing the Wheel?** By Dan Li and Younan Xia* Electrospinning provides a simple and versatile method for generating ultrathin fibers from a rich variety of materials that include polymers, composites, and ceramics. This article presents an overview of this technique, with focus on progress achieved in the last three years. After a brief description of the

Nowadays, thanks to the electrospinning process, polymeric fibers in nanoscale diameters (10–500 nm) are easily producible. During the last decade, the electrospinning technique has been greatly investigated and developed. One of the most important fields of study on the electrospinning process is the influence of effective parameters on

An electrospinning process is used to create polymer-based nanofibers with diameters ranging from 10-180 nm and lengths of up to several centimeters. By controlling the electrostatic field and the

Electrospinning; Grooved nanofibers; Polystyrene; Solvent systems – Background Electrospinning is a versatile nanofiber production technique using electrical force to stretch a charged polymer solution jet coupled with solvent evaporation and subsequent harvesting of solidified or semi-solidified nanofibers [1, 2]. Electrospun nanofibers are gaining increasing attention due to their distinct

Electrospinning of nanofibers is one fabricat ion method that has gained popularity over the last decade. It is a simple approach that provides exceptional …

27/02/2013 · Electrospinning of Nanofibers: Reinventing the Wheel?.” J.wiley.* and Constantine.Qi. Xuliang Deng. Y. Jing. Horst A. Xiabin. X.1002/adem. 2. Dalton. “Co-electrospinning of Core-Shell Fibers Using a Single-Nozzle Technique.3 Lixin Yang.doi. These scaffolds fulfill a similar purpose as the extracellular matrix in natural tissue. This would introduce multi-functionality (flame. ^ Alexander

The mixture of the cell and the salt solution) on nanofibers surface increases attraction power of the cell b( e- cause of salt and there may be some porosity as well on …

Electrospinning is a process of nanofibers production by high electrical field known since the beginning of the former century [1, 2]. It is a popular technology for …

Alumina nanofibers were prepared by a technique that combined the sol-gel and electrospinning methods. The solution to be electrospun was prepared by mixing aluminum isopropoxide (AIP) in ethanol, which was then refluxed in the presence of an acid catalyst and polyvinylpyrolidone (PVP) in …

Electrospinning was carried out using continuous equipment in which a horizontal electric field was generated between a nozzle system and a collector plate, and a web having a width of 300 mm was conveyed past the front side of the collector.

Furthermore, clinical application of electrospun nanofibers including wound healing, tissue regeneration, drug delivery and stem cell therapy are highly feasible due to the ease and flexibility of fabrication of making nanofiber with this cost-effective method using electrospinning. In this review, we have highlighted the current state of the art and provided future perspectives on electrospun

Silver ions have been widely used in various biomedical fields such as wound dressing materials, body wall repairs, augmentation devices, tissue engineering scaffolds, in this study, we prepared

Electrospinning of nanofibers: Reinventing the wheel?. Advanced Materials , 16: 1151 – 1170 . [Crossref] , [Web of Science ®] [Google Scholar] ), and electrospun nanofibers have shown excellent porous properties and vast application potential in diverse areas (Agarwal & Wendorffa, 2008 Agarwal, S. and Wendorffa, J.H. 2008 .

Electrospun fibers are explored as a new system for controlled drug delivery. Novel techniques capable of obtaining polymer nanofibers have been reported in the literature. They include solution blow spinning (SBS), which is a technique to produce polymer nanofibers in the same range as electrospinning, using pressurized gas instead of high

Nanofibers (NFs) of Ga-doped ZnO (GZO) were prepared by electrospinning of polymer–salts solution. Sintering profiles reported in the literature led to loss of the fibrous structure.

Electrospinning of nanofibers is one fabrication method that has gained popularity over the last decade. It is a simple approach that provides exceptional …

Electrospinning/electrospray of polyvinylidene fluoride

Electrospinning and Electrospun Nanofibers scirp.org